Applications:

For handling aggressive organic and inorganic fluids in

- Chemical industry

- Petrochemical industry

- Process engineering

- Sugar industry

- Biodiesel, bioethanol

- Fire-fighting systems / fire-fighting water

- Seawater desalination / reverse osmosis

- Condensate

- Hot water

- Brine

- Steel industry

- Heat transfer media

- Cleaning agents

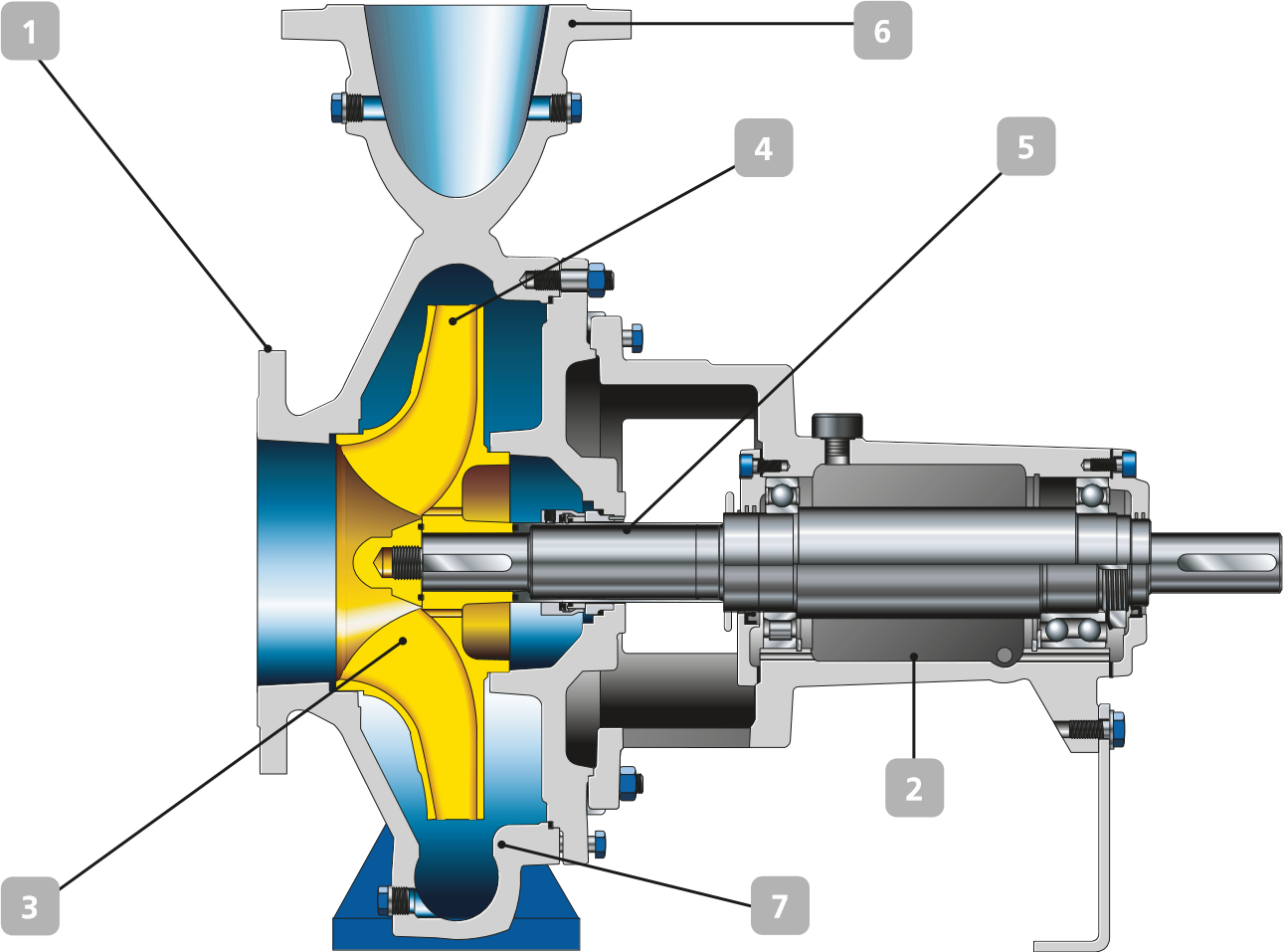

MegaCPK – Standardised Chemical Pump to ISO 2858 / ISO 5199 and Directive 94/9/EC (ATEX)

- Meets relevant standards

- Dimensions to ISO 2858, complemented by nominal diameters

- DN 25 and ≥ DN 200

- Design to ISO 5199

- Acceptance tests / inspections to ISO 9906

- High reliability and lower operating costsReduced energy consumption, optimised spare parts

concept and hard-wearing, service-friendly design - Energy efficiencyHydraulic characteristics optimised for excellent efficiency and NPSH, ensuring energy-efficient and environmentally friendly use of resources

- Lower investment costsDuty points required can be achieved with smaller pump sizes

- Large range of variants for all applicationsAll shaft seal types possible including gland packings, single or double mechanical seals and cartridge seals

- The right size for each application79 hydraulic systems: the best choice for all operating points

- Easy to serviceBack pull-out design and smaller spare parts stocks

| Material options |

|---|

| Grey cast iron JL1040/A48CL35 |

| Cast steel GP240GH+N/A216GrWCB |

| Stainless steel 1.4408/A743GrCF8M |

| Duplex steel 1.4593/1.4517/A995GrCD4MCuN |

| Super duplex 1.4573 / 1.4469.09 / A995 Gr. 5A |

| Special materials |

| Technical data | |

|---|---|

| Flow rate Q | Up to 2,700 m3 /h (50 Hz) Up to 3,300 m3 /h (60 Hz) |

| Head H | Up to 162 m (50 Hz) Up to 233 m (60 Hz) |

| Operating temperature t | -40 °C to +400 °C |

| Operating pressure p | Up to 25 bar |