Applications:

- Slip Recirculation

- Mixing Tank Transfer

- Slip Casting House

- Glazing

- Slurry Transfer

- Filter Press Feeding

- Sludge Transfer

- Effluent Transfer

- Loading & Unloading of Equilization Tank

- Raw Material Transfer

- Emulsation Transfer

- Solvent Transfer

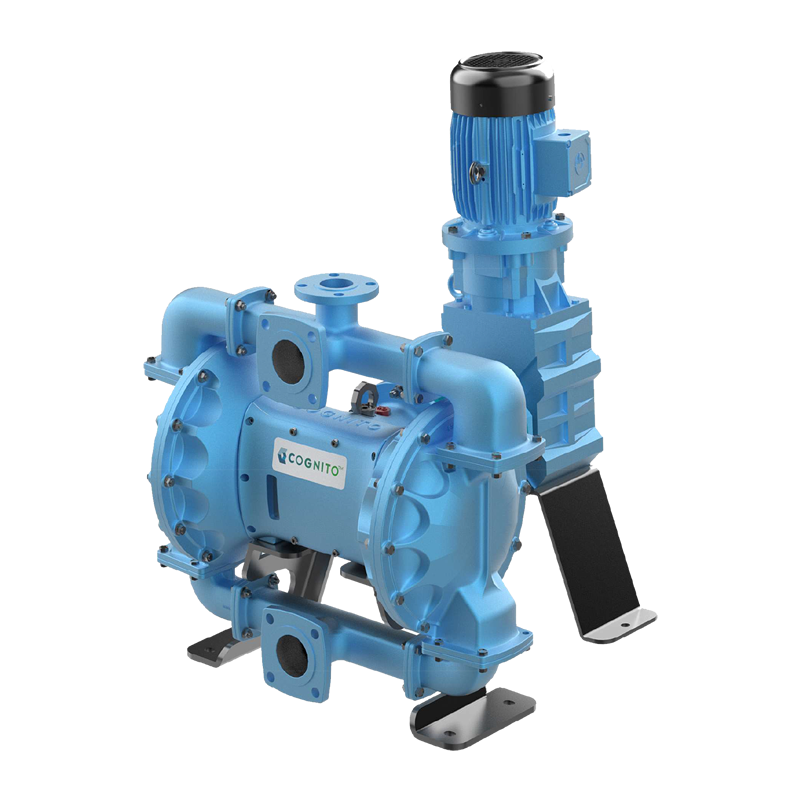

Highly Energy Efficient Pump with Significant Reduction in Energy Consumption

Smoothly Handles Highly Abrasive, Corrosive, Shear Sensitive & Viscous Fluids

Robust Mechanism with Hassle-Free Maintenance

Low MTTR and High MTBF

Remote Performance Monitoring of Pump

Patented Diaphragm Designed for Better

Performance and Longer Life

Reduced Operating Cost

Swift ROI/Payback

Technical Data

| Suction / Discharge Port Size : IN (MM) | 2″ (50) | 3″ (76) | 4″ (102) |

|---|---|---|---|

| Fluid Port Connection Type : Alum (SS) | 150# ANSI (FNPT) | 150# ANSI (BSP) | |

| Maxium Flow Rate GPM: | (LPM) 79 (300) | 135 (510) | 211 (800) |

| Max Operating Pressure : PSI (BAR) | 116 (8) | 87 (6) | |

| Ambient Temperature F (C) | -4°F to +131°F (-20°C to +55℃) | ||

| Operating Temperature | 14°F to 230°F (-10°C to +110C) | ||

| Solids Handing : IN (MM) | 0.19″ (5) | 0.27″ (7) | 0.35″ (9) |

| Heads Up To : FT (M) | 262 (80) | 197 (60) | |

| Displacement Per Stroke : GAL (L) | .39 (1.48) | .76 (2.9) | 1.25 (4.75) |

| Maximum Suction Life : FT (M) | 26+ Wet / 14 Dry (8+ Wet / 4.2 Dry)* | 26+ Wet / 18 Dry (8+ Wet / 5.5 Dry)* | |

| Motor & Gear Box : HP | 3hp & 5hp | 7.5hp & 10hp | |

| Sound Level | <80 db | ||

| *Applicable to Santoprene & PTFE Diaphragms only | |||

Material

| Size | Model Number | Wetted Parts | |

|---|---|---|---|

| Body | Diaphragm | ||

| 2″ | 2AS | Aluminum | Santoprene |

| 2AP | Aluminum | Santoprene Backup / PTFE | |

| 2SS | Stainless Steel | Santoprene | |

| 2SP | Stainless Steel | Santoprene Backup / PTFE | |

| 3″ | 3AS | Aluminum | Santoprene |

| 3AP | Aluminum | Santoprene Backup / PTFE | |

| 3SS | Stainless Steel | Santoprene | |

| 3SP | Stainless Steel | Santoprene Backup / PTFE | |