Applications:

- Water supply

- Drinking water supply

- Pressure boosting

- Irrigation systems

- Fossil-fuelled power stations

- Hot water supply

- Condensate transport

- Boiler feed applications

- Heating systems

- Filtering systems

- Fire-fighting systems

- Snow-making systems

- Washing plants

- Industrial plants

- Desalination plants

- Geothermal plants

- Heat recovery systems

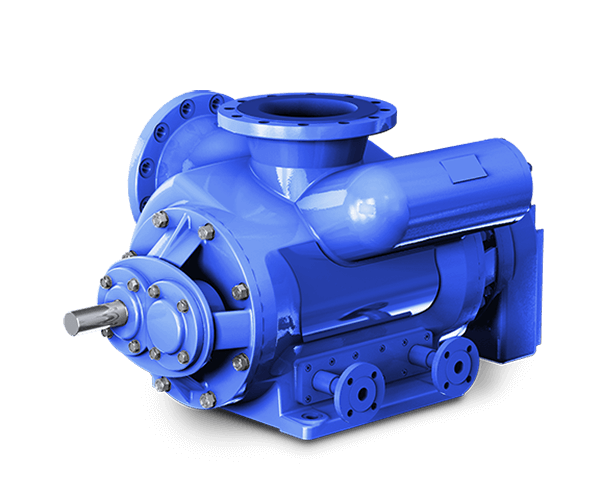

Versatile and flexible pump

Suction and discharge nozzles can be adjusted to the system as needed, even on site.

High operating reliability

- Special suction impeller designed for good performance and smooth running even under poor suction conditions or for handling fluids with low vapour pressure.

- Wear-resistant, self-aligning plain bearing made of silicon carbide.

- Axial thrust balancing ensured by balancing drum for a long service life.

Low operating costs

- Optimised hydraulic design and impellers trimmed to the duty point as a standard to ensure the system’s high efficiency.

- KSB SuPremE® IE5* synchronous reluctance motor, PumpMeter, as well as PumpDrive or PumpDrive R variable speed systems ensure optimal efficiency of the complete pump set and automatic adjustment to current demand, thus important energy savings are achieved.

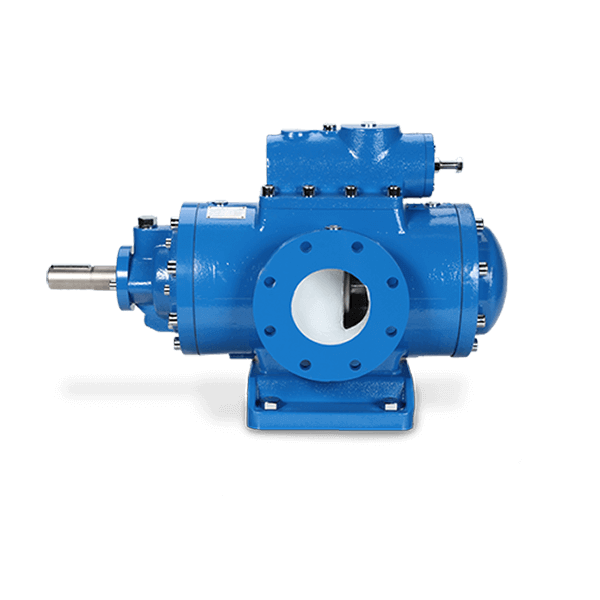

Service-friendly design, low spare parts costs

- Easy dismantling of bearing and shaft seal without the need to remove hydraulic components thanks to separate seal chamber/bearing housing as well as shaft protecting sleeves at the bearing and shaft seal.

- With some pump models, there is only one discharge-side seal. This reduces the costs for purchasing and storing spare parts.

| Material | |

|---|---|

| Cast iron | Bronze |

| Nodular cast iron (only for 200 and 250) | Cast steel |

| Duplex and super duplex stainless steel | Stainless steel |

| Technical Data | Size: 32 – 250 | |

|---|---|---|

| Flow rate | up to 1500 m3/h | 6604 Usgpm |

| Discharge head | up to 1000 m | 3280 ft |

| Pump discharge pressure | up to 100 bar | up to 1450 psi |

| Fluid temperature | -10 to + 200 °C | 14 to 392 °F |

| Frequency | 50 and 60 Hz, 2 and 4 poles | |